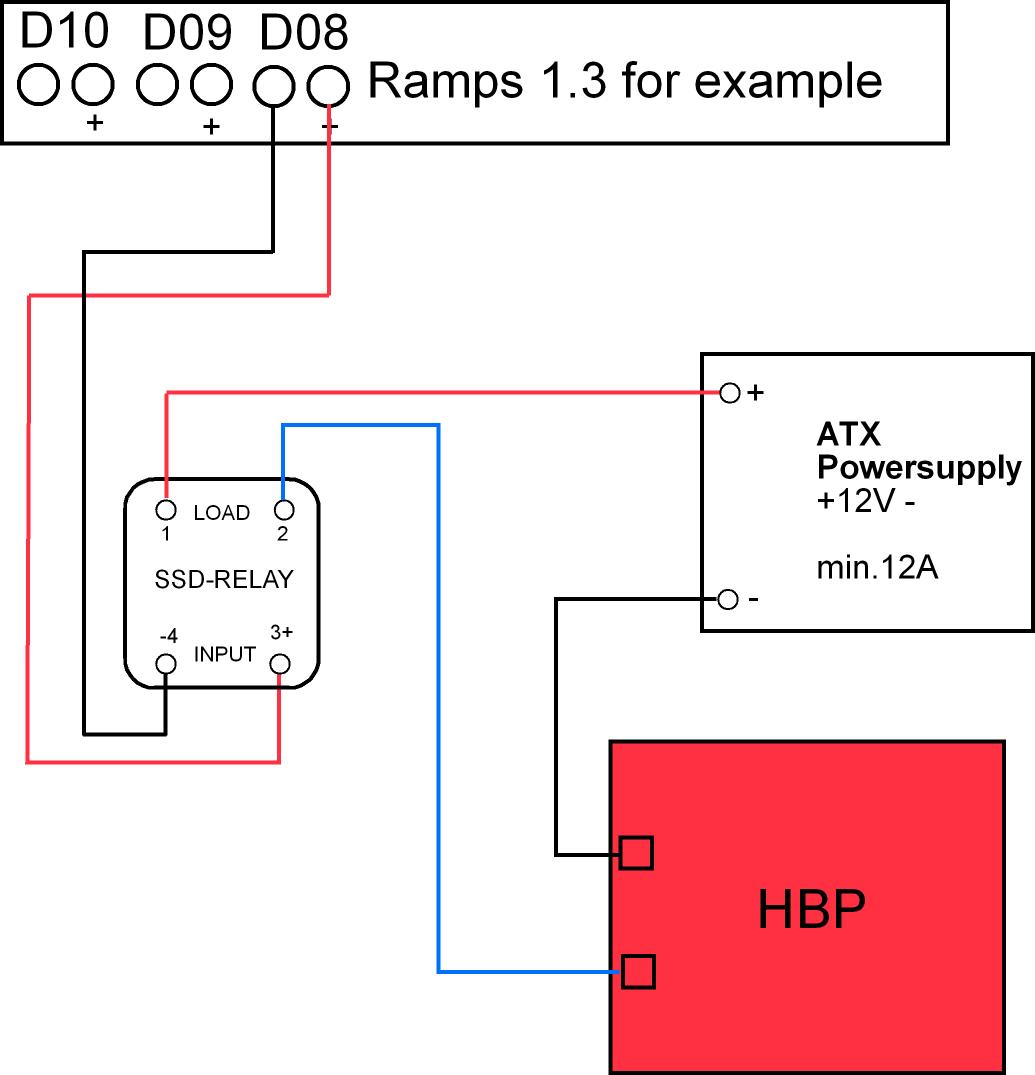

So after a week of tests with a small heat bed, I finally got a SSR-50 DA Solid State Relay to connect my 18x18 Monster Heatbed to my Gmax for temp control. When powered up in testing everything is fine. But once the heatbed gets to the right temp, it goesn't shut off. I can see the flashing lights on the RAMPS and the Relay in prep to shut-off. But the heatbed continues to get hotter.

Researching it seems I may need something like a bleeder resistor to keep current leakage that prevents the heat bed from turning off. Can any help me which knowing what exactly I need to purchase? Thanks!

Justin

Researching it seems I may need something like a bleeder resistor to keep current leakage that prevents the heat bed from turning off. Can any help me which knowing what exactly I need to purchase? Thanks!

Justin