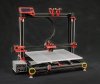

I saw the new 1.5 and XL yesterday at NY MakerFaire, and they looked fantastic - as does our fearless leader, Gordon, always

Really looking forward to the parts and plans for upgrading my 1.0 to 1.5 being published - or are they already posted here somewhere? The vertical Z-Axis support looks better and I'm sure it's more stable and easier to square up than the original "A Frame" design.

julia

Really looking forward to the parts and plans for upgrading my 1.0 to 1.5 being published - or are they already posted here somewhere? The vertical Z-Axis support looks better and I'm sure it's more stable and easier to square up than the original "A Frame" design.

julia