Hi Joshua,

I've joined Gary this year and have started working on the printer (gMax 1.5+) again. I've gone through all the setting etc. that I can find on this printer and still we are not 100% satisfied with our results.

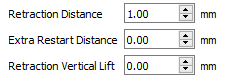

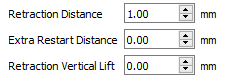

1. In terms of retraction discussed above, which one of the three simplify3d setting are you referring to?

I've seen some guys refer to retraction as Vertical lift and maybe this is where the 3-5mm is actually coming from. We have tried 1mm Retraction distance and also anything from 3-5mm retraction vertical lift with not much luck. This was done to improve the stringing that we find. I know we can just cut it or blow with a hot air gun but what amount of stringing is according to you acceptable. I will try and post a photo as soon as possible on the results we get.

2. Then to combat the stringing I've read about quite a few different methods to prevent it. Some say just to ignore retraction at all. Again I'm not sure which retraction they are referring too. The other thing to try and do is increase movement speeds when not printing. We had some success with this. I would just like to know what the speed setting limits are of the gMax 1.5+ for the following:

- Extruder Tab (Simplify3d) -> Retraction Speed ?

- Speed Tab -> x/y axis movement speed?

- Speed tab -> Z axis movement speed?

On the z-axis movement speed setting. If one hovers the mouse on that setting it will bring up a "hint" saying that this setting should match actual z-axis movement when moving between layers as closely as possible to get accurate print times. But I'm confused to where I can find the actual z-movement speed for moving between layers.

3. Before starting to print, while the extruder is heating up, some material starts to ooze from the extruder. When the skirl outline starts printing one has this blob of material now stuck to the extruder. Is there a different approach one could take to remove that before a print. We sometimes quickly clean the extruder off before it moves off to print. But this is a tricky situation.

4. While the print is going there is some material buildup on the extruder after a while. This eventually forms a blob of material that gets dropped onto the print at some random stage in the print. Is there a way to prevent this buildup of material, are we doing something wrong?

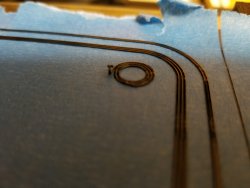

5. We have had some issues with the x/y axis not scaling properly. A circle would print more ellipse. We have found that the y-axis (bed) was too loose and set the wheels to touch the beams properly etc and the print was a lot better. But now Im suspecting the x axis has gone too. We've set the wheel there too but something is still off. I notice this when printing 3dBenchy. The bow does not scale properly and the line running there is not smooth like it should be. How do I know that the tension in the belts are correct for the x and y axis?

6. Bed levelling

It seems when we include the home all in the script before a print starts that the bed leveling gets undone. We are running Marlin 1.1.9 (gCreate Version) of the firmware and we are almost sure that doing a home all in the script wipes our bed levelling. It was recommended as far as I can remember from gCreate that we remove the bed levelling from the start scrip and that we only require to do the bed levelling once and it will be saved to EEPROM. We have found that doing the bed leveling from the printer menu (which also includes having the extruder move to home position) before a print and having no home all in the script works best. Is this a know issue? Is this possible?

Info:

- We are printing CRON PETG 220-250 degC. We have set the temperature to 240-245. We've done a temperature bridge test print to find the best spot. If we go lower the layer adhesion is not good. Of we go to higher the stringy is just excessive. We've had some good prints but it doesn't last. Maybe

- We have the Marlin 1.1.9 gCreate Firmware on.

- We are using a 0.4mm E3D extruder tip.

Is it possible to get a sample of a print from this printer shipped to us, maybe we are expecting to much from the printer as it is a large format printer and the resolution might just not be what we expect. Photos of pre-processed prints would also be great. We just want to know what we should expect.

I'll post some photos of prints as soon as possible.

Regards,

Quintin.