There are many different 3D printing techniques. The best known techniques are: Selective Laser Sintering (SLS), Stereolithography (SLA), and Fused Deposition Modeling (FDM). The SLS technique functions by repeatedly dosing a layer of powder on a powder bed. The form of the product is created by putting the laser on a selection of the powder bed. SLA functions by curing resin using a UV-laser, creating a product layer after layer. FDM is the most popular contemporary technology to create products.

FDM technology

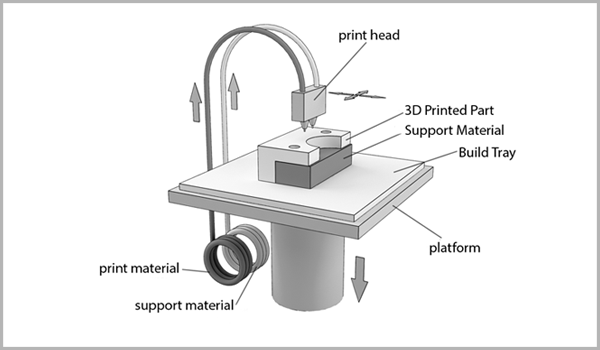

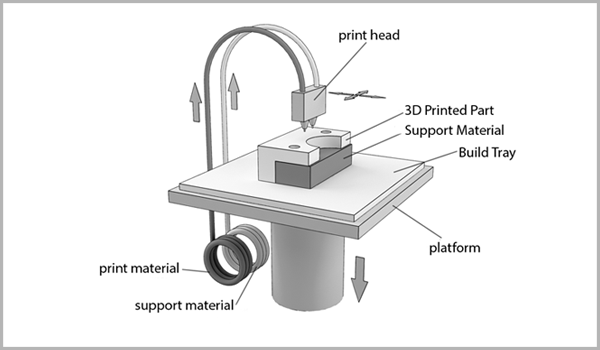

The FDM technique is based on extrusion. By means of a print head, a molten layer of plastic is deposited on the print bed, which then adheres. Once the first layer has been drawn, the print bed drops and a new layer is built on the previous layer. This is repeated several times, ultimately resulting in a 3D printed model.

Lower costs

Most of the time when companies choose the FDM technology, the reasons behind it are the lower cost and the user friendliness of this technique. Compared to other techniques, FDM is a lot cheaper. For companies it is very important to know whether producing by means of 3D printing technique is cheaper than utilising the traditional way of producing. The powder that is used in SLS and the liquid for SLA are very costly for example. In contrast, for the material that is used in FDM technology, the filament, costs are much lower. For this reason FDM technology is more attractive to many companies. 3d printing services in vadodara,baroda,ahmedabad,surat,rajkot,bhavnagar,vapi,gujarat india

ABS

ABS (Acrylonitrile Butadiene Styrene) is an petroleum-based polymer. It is very resistant to high temperature which makes this material perfect for real-world components. It is a pretty cheap material allowing for cost effective prototyping. ABS is the go-to material for most 3D printers. Along with PLA, it is the most common material used for desktop 3D printing.

3d printing PLA

Made from renewable resources, Polylactic Acid is green 3d printing material. It has a moderate price point on the market and has various desirable properties and technical specifications which makes it the perfect 3D printer filamentfor hobbyists. 3d printing service vadodara,baroda,ahmedabad,surat,rajkot,bhavnagar gujarat maharashtra india

Nylon

Nylon is a strong and durable synthetic polymer with a translucent silky finish, also called white plastic. It is also sold for a moderate price which makes it widely used for the production of household items. Want to get started with printing Nylon? Check out our in-depth article here.

Applicable 3d printing Technologies

Fused Deposition Modeling (FDM)/FFF

HIPS

HIPS stands for high impact polystyrene. Polystyrene is one of the most common materials in our daily lives. HIPS is a low cost material, with a higher strength level than the standard polystyrene. HIPS is used for various things like plastic signs and thicker containers.

Alloy 910

PVA

PVA(Polyvinyl Alcohol) is a water soluble material that is great for printing but can also act as a support material. This makes it very useful for complex designs where support removal can be damaging or tricky. Thus many users print support with it can leave the result in a body of water overnight and retrieve their desired print.

FDM technology

The FDM technique is based on extrusion. By means of a print head, a molten layer of plastic is deposited on the print bed, which then adheres. Once the first layer has been drawn, the print bed drops and a new layer is built on the previous layer. This is repeated several times, ultimately resulting in a 3D printed model.

Lower costs

Most of the time when companies choose the FDM technology, the reasons behind it are the lower cost and the user friendliness of this technique. Compared to other techniques, FDM is a lot cheaper. For companies it is very important to know whether producing by means of 3D printing technique is cheaper than utilising the traditional way of producing. The powder that is used in SLS and the liquid for SLA are very costly for example. In contrast, for the material that is used in FDM technology, the filament, costs are much lower. For this reason FDM technology is more attractive to many companies. 3d printing services in vadodara,baroda,ahmedabad,surat,rajkot,bhavnagar,vapi,gujarat india

ABS

ABS (Acrylonitrile Butadiene Styrene) is an petroleum-based polymer. It is very resistant to high temperature which makes this material perfect for real-world components. It is a pretty cheap material allowing for cost effective prototyping. ABS is the go-to material for most 3D printers. Along with PLA, it is the most common material used for desktop 3D printing.

3d printing PLA

Made from renewable resources, Polylactic Acid is green 3d printing material. It has a moderate price point on the market and has various desirable properties and technical specifications which makes it the perfect 3D printer filamentfor hobbyists. 3d printing service vadodara,baroda,ahmedabad,surat,rajkot,bhavnagar gujarat maharashtra india

Nylon

Nylon is a strong and durable synthetic polymer with a translucent silky finish, also called white plastic. It is also sold for a moderate price which makes it widely used for the production of household items. Want to get started with printing Nylon? Check out our in-depth article here.

Applicable 3d printing Technologies

Fused Deposition Modeling (FDM)/FFF

HIPS

HIPS stands for high impact polystyrene. Polystyrene is one of the most common materials in our daily lives. HIPS is a low cost material, with a higher strength level than the standard polystyrene. HIPS is used for various things like plastic signs and thicker containers.

Alloy 910

PVA

PVA(Polyvinyl Alcohol) is a water soluble material that is great for printing but can also act as a support material. This makes it very useful for complex designs where support removal can be damaging or tricky. Thus many users print support with it can leave the result in a body of water overnight and retrieve their desired print.