TPU & Other Flex Filaments

If you are looking for a durable, flexible, and elastic material than TPE or TPU is the choice. TPU (Thermoplastic Polyurethane) is a compound of hard plastic and rubbers suitable and mostly used for FDM printing. This blend allows TPU to stretch and bend with ease making it perfect for shock absorbing, vibration dampening, cases or covers and even fashion. TPU can be tricky to print with because of its stringy nature and its tendency to squeeze out of the openings in your extruder drive, but once you dial it in, it can be one of the most fun and functional materials to print!

MEDIUM-HARD

Pros

+ Widely used throughout FDM industry+ Soft and Flexible

+ Impact Resistant

+ Many Applications

+ Variety of Hardnesses

Cons

- Difficult to Print- Bridging and Overhangs can be Challenging

- Slow to Print

- Can be Stringy

Print Settings

HotEnd Temp: Check Material Notes ( On the higher end of the scale)

Bed Temp: Not required on acrylic. 50C for heated bed

Layer Height Range: 0.16mm - 0.32mm

Cooling: Ramp up from 40% to 80%

Retraction: 0.75mm-1.15mm

First Layer Height: 125%

First Layer Width: 125%

First Layer Speed: 60%

Printing Tips and Tricks

TPU Durometer

There are many different kinds of TPU and TPE with different Durometer ratings. Durometer (or Shore Hardness) is defined as a material's resistance to indentation, or in other words, how soft (or hard) a given material is. Most TPUs will have their durometer listed on their material info sheet. Most often you will see it listed as a 2-Digit number followed by a letter, such as "85A", this is an example of a softer, more elastic filament whereas 45D is a harder, more rigid TPU. The higher the number, the harder the material. .

There are many different kinds of TPU and TPE with different Durometer ratings. Durometer (or Shore Hardness) is defined as a material's resistance to indentation, or in other words, how soft (or hard) a given material is. Most TPUs will have their durometer listed on their material info sheet. Most often you will see it listed as a 2-Digit number followed by a letter, such as "85A", this is an example of a softer, more elastic filament whereas 45D is a harder, more rigid TPU. The higher the number, the harder the material. .

Print TPU Hotter

When you purchasing TPU, the manufacturer will always include a recommended printing temperature. When looking at that range it is always better to aim hotter than it is cooler. TPU is can be very flexible and can get backed up in the drive gear if it requires to much force to push the filament out. The best way to increase the ease of flow and relieve the pressure is to print hot!

When you purchasing TPU, the manufacturer will always include a recommended printing temperature. When looking at that range it is always better to aim hotter than it is cooler. TPU is can be very flexible and can get backed up in the drive gear if it requires to much force to push the filament out. The best way to increase the ease of flow and relieve the pressure is to print hot!

The Slower the Better

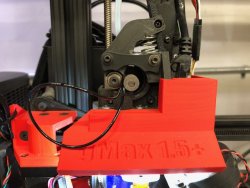

If you are having difficulty printing TPU you're more than likely printing too fast. TPU has the tendency to take the path of least resistance, If there is even the smallest back up in the nozzle your TPU will squeeze its way out of any opening in your drive gear it can (Picture above). This cause prints to fail, nozzles to clog and above all else endless frustration. So Just like increasing your temperature, slowing down your print will ease the stress on the filament as its being pushed through the drive gear. This leaves more time for the filament to heat and melt in your hotend and allows everything to flow freely will no resistance.

If you are having difficulty printing TPU you're more than likely printing too fast. TPU has the tendency to take the path of least resistance, If there is even the smallest back up in the nozzle your TPU will squeeze its way out of any opening in your drive gear it can (Picture above). This cause prints to fail, nozzles to clog and above all else endless frustration. So Just like increasing your temperature, slowing down your print will ease the stress on the filament as its being pushed through the drive gear. This leaves more time for the filament to heat and melt in your hotend and allows everything to flow freely will no resistance.

Dialing in Retraction

Dialing in your retraction settings are key for printing TPU. Many people suggest printing with no retraction at all, but this can lead to stringy, pimply prints but If your retraction value is too high then your prints will clog and the filament will jam.

Finding the perfect balance can be tricky and it will depend on the durometer of your TPU. The harder and more ridged your TPU is, the more retraction you can use because it's less likely to stretch and deformed as its yanked in and out of the hotend. This, unfortunately, is a trial and error process, its best to start at your normal retraction settings and work your way down.

Dialing in your retraction settings are key for printing TPU. Many people suggest printing with no retraction at all, but this can lead to stringy, pimply prints but If your retraction value is too high then your prints will clog and the filament will jam.

Finding the perfect balance can be tricky and it will depend on the durometer of your TPU. The harder and more ridged your TPU is, the more retraction you can use because it's less likely to stretch and deformed as its yanked in and out of the hotend. This, unfortunately, is a trial and error process, its best to start at your normal retraction settings and work your way down.

Larger Nozzles

Relieving pressure in the nozzle is so important while printing TPU. Along with printing Hotter and slower, printing with a larger diameter nozzle such as a 0.8mm or even up to a 1.2mm can drastically increase your success rates while printing TPU. The larger nozzles allow TPU flow through the nozzle much more freely.

Relieving pressure in the nozzle is so important while printing TPU. Along with printing Hotter and slower, printing with a larger diameter nozzle such as a 0.8mm or even up to a 1.2mm can drastically increase your success rates while printing TPU. The larger nozzles allow TPU flow through the nozzle much more freely.

Attachments

-

71.1 KB Views: 1,301

Last edited: