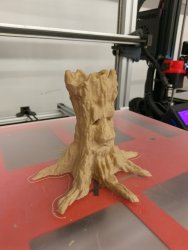

WoodFill PLA

Woodfill PLAs are composite materials that use a combination of wood fibers and PLA plastics to create a filament that has the appearance of wood but the printability of PLA. Woodfills can be found with many different kinds of wood such as Bamboo and hardwoods with varying colors. Its a great material for fun projects but it lacks the strength of other filaments and can be challenging to print cleanly but if you master it, it can be one of the most visually appealing materials out there!

INTERMEDIATE

Pros

+ Aesthetically Pleasing+ Good bed adhesion

+ Color can change depending on print temp

+ Can sand or stain

+ Low warping

+ Biodegradable

Cons

- Weak and Brittle- Lots of stringing

- May stick to much to acrylic

Print Settings

HotEnd Temp: 180C - 210C

Bed Temp: Not required on acrylic. 50C for heated bed

Layer Height Range: 0.16mm - 0.32mm

Cooling: Ramp up from 40% to 80%

Retraction: 0.95mm-1.5mm

First Layer Height: 125%

First Layer Width: 125%

First Layer Speed: 60%

Bed Temp: Not required on acrylic. 50C for heated bed

Layer Height Range: 0.16mm - 0.32mm

Cooling: Ramp up from 40% to 80%

Retraction: 0.95mm-1.5mm

First Layer Height: 125%

First Layer Width: 125%

First Layer Speed: 60%

Printing Tips and Tricks

Many Different Kinds of Woodfills

Woodfill PLAs are a composite mixture of PLA and Wood dust so there are many different variations to choose from such as standard light wood, Dark woods, bamboo, and redwoods. Some brands even have budget wood fills which can give a similar effect but is made from real wood. This allows for a ton of freedom when choosing your filament.

Woodfill PLAs are a composite mixture of PLA and Wood dust so there are many different variations to choose from such as standard light wood, Dark woods, bamboo, and redwoods. Some brands even have budget wood fills which can give a similar effect but is made from real wood. This allows for a ton of freedom when choosing your filament.

Sanding and Staining.

One of the coolest aspects of Woodfill is that since it's made up of almost half wood dust you can sand and stain your parts just like real wood! The wood dust within the plastic can take stain surprisingly well.

One of the coolest aspects of Woodfill is that since it's made up of almost half wood dust you can sand and stain your parts just like real wood! The wood dust within the plastic can take stain surprisingly well.

Great Bed Adhesion, No Heated Bed Needed

Wood fill has great bed adhesion and sticks great to most surfaces, Almost a little too well. When Printing on acrylic be sure not to print too close to the bed, Wood fill can stick so much that the bottom layer has been known to stay stuck to the acrylic bed when trying to remove your print.

Although you can use one, heated beds are not required when printing PLA. This makes it an ideal material for safe and low-power printing.

Wood fill has great bed adhesion and sticks great to most surfaces, Almost a little too well. When Printing on acrylic be sure not to print too close to the bed, Wood fill can stick so much that the bottom layer has been known to stay stuck to the acrylic bed when trying to remove your print.

Although you can use one, heated beds are not required when printing PLA. This makes it an ideal material for safe and low-power printing.

Prone to Stringing

Woodfill PLA is very prone to stringing so making sure your retraction is set just right is key to getting great woodfill prints. Bumping up your retraction is necessary to avoid blobs and stings. The picture on the left is woodfill printed with standard PLA retractions settings.

Woodfill PLA is very prone to stringing so making sure your retraction is set just right is key to getting great woodfill prints. Bumping up your retraction is necessary to avoid blobs and stings. The picture on the left is woodfill printed with standard PLA retractions settings.

Tempatures Can Affect Color

When printing with wood fill the temperature that you are printing at can affect the color of the print. The hotter your hot end the darker the filament will extrude. This allows for a lot of cool creative opportunities by changing temps mid print.

When printing with wood fill the temperature that you are printing at can affect the color of the print. The hotter your hot end the darker the filament will extrude. This allows for a lot of cool creative opportunities by changing temps mid print.

Example Images

Attachments

-

98.9 KB Views: 1,208

Last edited: