PLA - Polylactic Acid

Of all the 3D printing materials PLA is by far the easiest and cleanest filament to use. Whether you are just starting out or a professional this is a great all-around filament. Although it's argued that it's more brittle and weak than other materials such as ABS, it's strong enough for most applications and doesn't come with the headaches. If you are looking for great print quality with minimal effort, PLA is the way to go!

EASY

Pros

+ Widely used throughout FDM industry+ Inexpensive

+ Many color options

+ Easy to work with

+ Low warping

+ Can be heat treated

+ Biodegradable

Cons

- Warps in High Temperature- Lots of poor quality variations

- Requires cooling

Print Settings

Bed Temp: Not required on acrylic. 50C for heated bed

Layer Height Range: 0.16mm - 0.32mm

Cooling: Ramp up from 40% to 80%

Retraction: 0.75mm-1.15mm

First Layer Height: 125%

First Layer Width: 125%

First Layer Speed: 60%

Printing Tips and Tricks

PLA is a "Low Warp" Material

PLA very easy to work with due to its low warping but good bed adhesion is still key. A filament will tend to warp if it contracts a lot during cooling. Sometimes, as filament cools higher up on a model, it pulls together causing the edges of a model to curl.

Make sure your acrylic or glass bed is prepped by either sanding or applying adhesives, follow the steps in the article Achieving the Perfect First Layer for a full tutorial.

PLA very easy to work with due to its low warping but good bed adhesion is still key. A filament will tend to warp if it contracts a lot during cooling. Sometimes, as filament cools higher up on a model, it pulls together causing the edges of a model to curl.

Make sure your acrylic or glass bed is prepped by either sanding or applying adhesives, follow the steps in the article Achieving the Perfect First Layer for a full tutorial.

Heated Bed Not Necessary

Although you can use one, heated beds are not required when printing PLA. This makes it an ideal material for safe and low-power printing.

If you are printing a part with a small footprint, add several "brims" to the edge of the part, on a raft or add "elephants feet" to ensure enough adhesion.

Although you can use one, heated beds are not required when printing PLA. This makes it an ideal material for safe and low-power printing.

If you are printing a part with a small footprint, add several "brims" to the edge of the part, on a raft or add "elephants feet" to ensure enough adhesion.

Benefits From Cooling

PLA benefits heavily from good part cooling. Part cooling improves bridging, overhangs, and general print quality. We recommend starting at around 45% cooling for layer 3 and ramp up the cooling every 3 layers until you reach a max of 85%.

PLA benefits heavily from good part cooling. Part cooling improves bridging, overhangs, and general print quality. We recommend starting at around 45% cooling for layer 3 and ramp up the cooling every 3 layers until you reach a max of 85%.

Settings are Versatile

PLA can be printed in a wide range of layer heights, speeds and temperatures. By changing the nozzle size you can print PLA from 120 microns up to 750 microns with small changes to settings. You can also change the temperature of the material to increase bed bonding on your first layer or to change the part finish from glossy to matte.

PLA can be printed in a wide range of layer heights, speeds and temperatures. By changing the nozzle size you can print PLA from 120 microns up to 750 microns with small changes to settings. You can also change the temperature of the material to increase bed bonding on your first layer or to change the part finish from glossy to matte.

Excellent at Bridging

While PLA is considered a "low warp" filament it still does cool while contracting. This property makes it suitable for bridging long gaps without requiring support below.

While PLA is considered a "low warp" filament it still does cool while contracting. This property makes it suitable for bridging long gaps without requiring support below.

Temperature Dependant

PLA can be printed anywhere from 180C to 210C. The temperature you choose will depend on the model you're printing and the brand of filament you're using. The higher the temp, the better your layers will bond and the stronger your part will be, the lower the temp the better your overhangs and bridges will be. As long as you have adequate cooling you should be able to achieve more than acceptable bridging no matter what temperature you are at.

PLA can be printed anywhere from 180C to 210C. The temperature you choose will depend on the model you're printing and the brand of filament you're using. The higher the temp, the better your layers will bond and the stronger your part will be, the lower the temp the better your overhangs and bridges will be. As long as you have adequate cooling you should be able to achieve more than acceptable bridging no matter what temperature you are at.

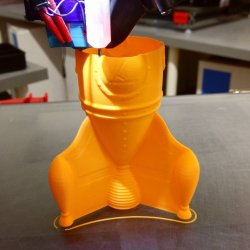

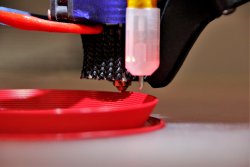

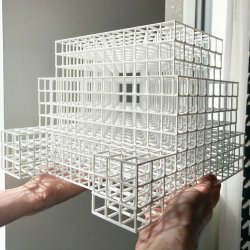

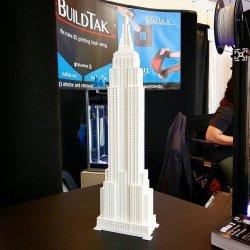

Example Images

Attachments

-

110.4 KB Views: 1,240

Last edited: